Forging can be carried out by many methods, some of which are listed below:

Extrusion And Drawing Process

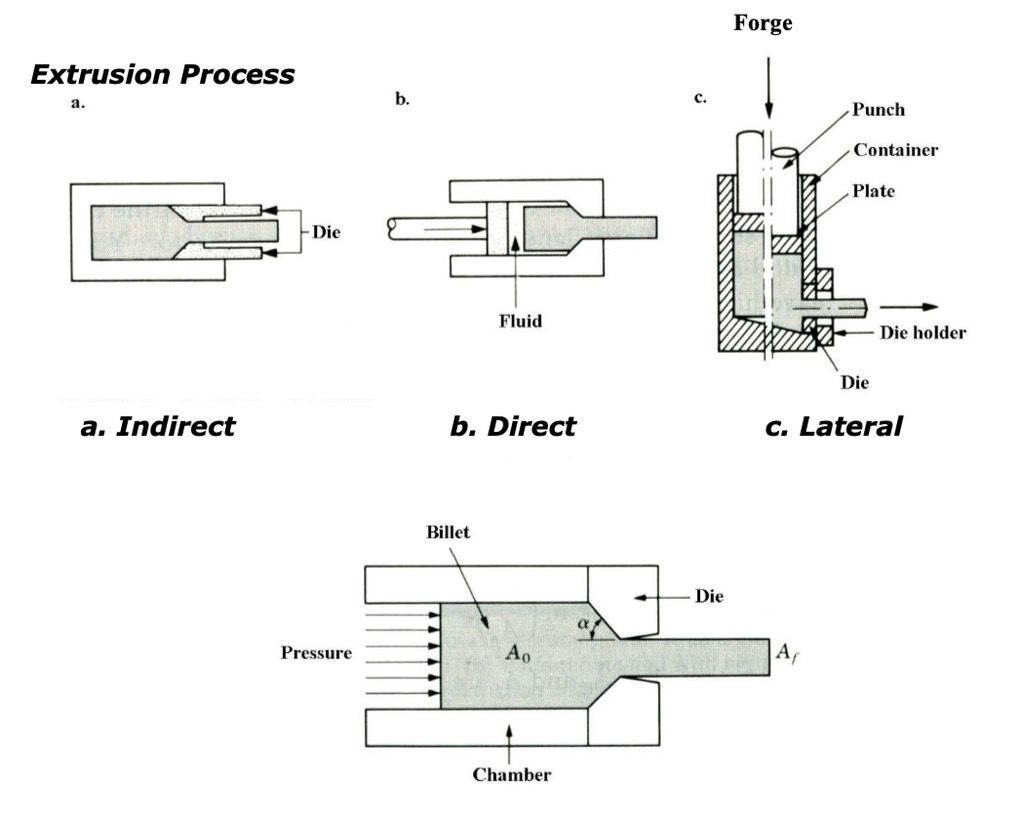

Extrusion is the process which pushes material through a shaped die a lubricant is often employed to reduce friction through the dies and varies with the material extruded i.e. glass may be used as a lubricant when dealing with some steels. The lubricant is generically referred to as “Soap”. There are two main types of extrusion process:

- Direct extrusion – a hot billet is placed in a chamber, then forced out under pressure through a die opening.

- Indirect (or reverse) extrusion – the billet is held within a chamber, the die holder is then forced into the billet extruding the shaped section.

Extrusion is normally carried out at elevated temperatures termed hot extrusion to increase the ductility of the material and therefore the ease in which the extrusion can be achieved. After extrusion a thin residual shell known as “Skull” is sometimes left in the chamber, the existence of skull confirms that the extruded material is free of oxides.

This process is normally associated with non-ferrous (low melting point) materials and classified as a high energy process to form the product, it is rarely used for high melting point materials unless difficult to forge or roll.

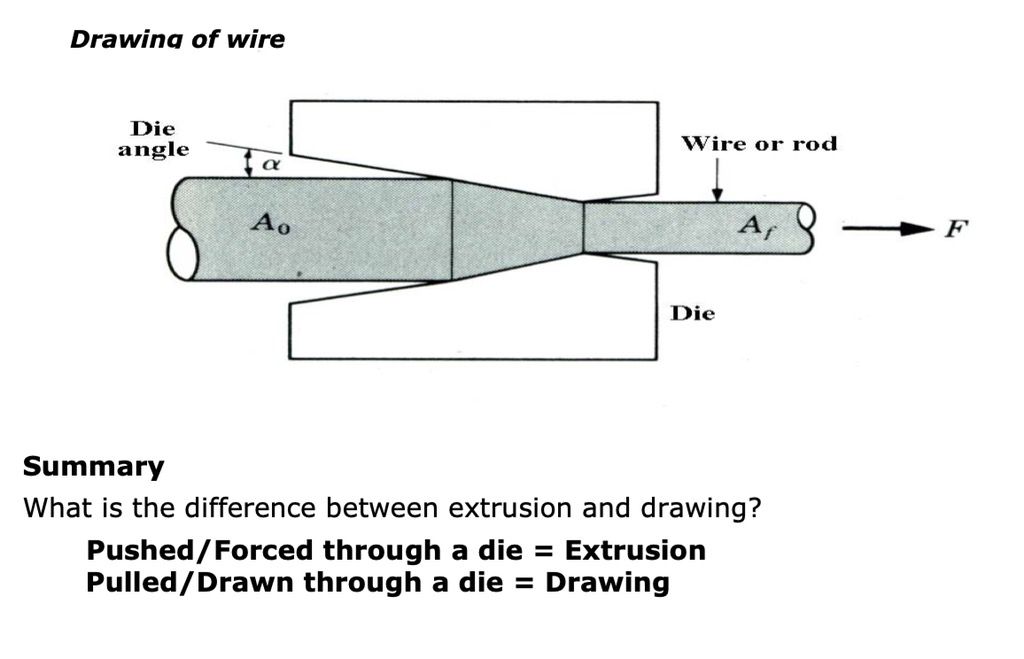

Drawing is a manufacturing process which pulls material through a single, or a series of, drawing die(s) to reduce its cross section.

Although similar in process, drawing is different from extrusion, because in drawing the material is pulled, rather than pushed, through the die. Drawing is usually performed at room temperature. As the wire is pulled through the die, its volume remains the same, so as the diameter decreases, the length increases.

Rod and bar drawing refers to the drawing of larger cross sections, wire drawing refers to the drawing of relatively smaller cross sections. The enormous amount of electrical wire and cable produced by this manufacturing method makes wire drawing a major modern industrial

process. An example of product produced in a continuous wire drawing machine is telephone wire.

During the drawing process intermediate anneals may be required to counter the effects of cold working, and to allow for further drawing. A final anneal may also be used on the finished product to maximize ductility and electrical conductivity.

Lubrication in the drawing process is ideal for maintaining good surface finish and long die life as its application can help control the forces and metal flow. The following are some different methods of lubrication:

- Wet drawing: the dies and wire or rod are completely submersed in lubricants. Lubricant in this case is typically some kind of oil containing chemical additives.

- Dry drawing: applies the lubrication as the wire or rod passes through a container/box of lubricant (i.e. ‘soap’) which coats the surface of the wire or rod.